Yes, you can. No, you shouldn't.

I have 2 sets of ~2014 Easton EA90 wheels with R4 hubs. They're cheap, generally reliable, easy to service, and when they're working well, will spin for DAYS. Both sets came to me with 10-speed R4 freehubs, and both of them are running 11-speed upgraded freehubs.

One set of these wheels came with my first (used) road bike, and the other I picked up at Performance Bicycle before they imploded for $300 because of a broken axle. That broken axle gave me a chance to learn all about how these wheels are put together, and where/how to source parts for Easton R4 hubs, which is important because these wheels love to eat bearings (no joke--I've spent more in bearings than I have on the actual purchase of the wheels).

At the actual axle interfaces it's not a big deal: 6901s & 6902s are pretty easy to source, and you don't even need to go with expensive stuff: it's not going to last more than a couple thousand miles anyway--why bother with ceramic or higher ABEC certifications?

But the freehubs? Man, what a pain. Easton designed these to be unserviceable. And expensive. At $80 a pop, these things are the most expensive component on my bike by size and service interval, with each lasting only about 2500 miles. Across 2 wheelsets, I've gone through 5. Those $300 wheelsets aren't so inexpensive now.

So after slapping on a brand new chain and heading out for my first ride in a light rain, what should happen but the chain goes slack while freewheeling. Classic Easton freehub failure. I came home and tried to order freehub #6, and lo and behold they're no longer made. Classic Easton parts availability.

I had tried once before to figure out the inner workings of these things, but to no avail: I couldn't press out the cartridge bearings, and bashing them with a dead-blow hammer just resulted in a pile of little balls on the bench.

But my options were now limited by availability of parts: try again to figure out how to service these bearings or buy new wheels. Option B is a non-starter because I'm not buying more rim-brake wheels, which means it's either fix these wheels or buy a new bike. Once again, option B is probably not a realistic choice at the moment.

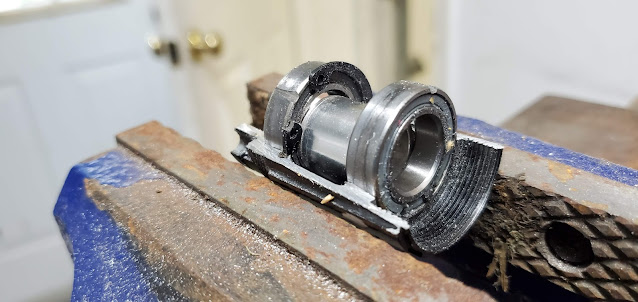

What I do have, though, is the original 10-speed freehub and a cutoff wheel. I put that old bugger in the vice and sliced it in half to reveal the inner construction, and the reason why I'd been unsuccessful the first time around: the dreaded circlip.Long the bane of auto mechanics the world over for its uncanny ability to shoot across the room to never be seen again, this is the first time I've encountered their ilk on a bicycle. Luckily I still have my circlip pliers and good lighting.

Bisecting the old freehub also revealed that the spacer between the inner & outer bearings should be easy enough to push aside to gain purchase on the outer bearing.

Unfortunately the only real way to remove that outer bearing is with striking force on the inner race, which is pretty much guaranteed to destroy the bearing.

So if your goal was to just replace the inner, you're probably out of luck. Do be careful not to apply the striking force to the spacer because you will damage it. Once you've smashed the outer bearing out and dropped the spacer under your workbench, you can get that horrid circlip out. It's a beefy one in a deep-set groove, so make sure your tools are in good working order.

Then it's time, once again, to smash out a bearing. And I say smash because, once again, you're only going to be able to apply force to the inner race. It's a horrible design. And this bearing you get to smash twice because it's the same size as the outer one, so you have to align it to the outer's shell and force it through there, too.

At this point it might be convenient to have a quick discussion about bearing anatomy. Here's a pic:

Sirs "Not Appearing in This Film" are the seals that sit on either face to keep the grease in and the dust & water out. Water is the sworn enemy of a precision bearing. In an ideal situation, pressure is applied principally either from the outside-in or from the inside-out, but always (always ALWAYS) vertically. Much care must be taken to ensure the load on the bearing aligns with its intended purpose. There are, for instance, angular-contact bearings that beef up the shoulders for transverse loads. These are not they. There are also needle bearings which replace the balls with roller pins (or needles--hence the name) for precision loads. These seem like they'd be ideal for bicycles, but no load on a bicycle is truly precisely aligned (Hambini explains this amazingly well in his anti-GXP rant), so ball bearings are the best bet.I pressed in the Amazon bearings, reloaded the circlip, re-aligned the inner sleeve, and mounted it up, and lo and behold...the freehub wouldn't turn with the wheel. Well crap. Pulled it back apart and soaked the pawls in bar & chain oil just to be sure there wasn't some weird resistance in the actual freehub interface, but no: nothing. It would turn, but only by hand.

So I smashed those shitty bearings back out and gambled on the amount of damage done to the originals during disassembly, because dammit I want my bike back, and amazingly, the damage wasn't *too* bad (there are 2 little crunches per wheel-rev, but a good firm twist of the wheel still takes about 30 seconds to spin down).

The trickiest part to reassembling these is that there is no preload adjustment between the inner & outer, but the sleeve needs to sit firmly in place between them, with nothing "sleeving" the outer races. Go too light and the sleeve flops around; go too tight and it applies lateral force to the shoulders, which will eat the races. That means Easton presses these things in with a precision instrument that I do not have, and I ended up pressing & testing about 10 times before I got to a point where I dared not add any more pressure.

The "right" pressure is functionally unknowable, but you'll certainly know when you exceed it (bearings won't turn), and at that point the only thing you can do is press the outer back out and start over.

At this point I'm not interested in trying to source additional 15267's. Better ones would cost more than half the price of the whole unit (even though that's no longer available). I think I'm done chasing this wheel. It doesn't help that the aluminum end caps on these axles are butter-soft aluminum and now ALSO discontinued.

Long story short? You can do this! I believe in you! But don't bother, because it's a waste of time. So now I guess it's time to start shopping for a new bike while these bearings slowly eat themselves.